Research and developement

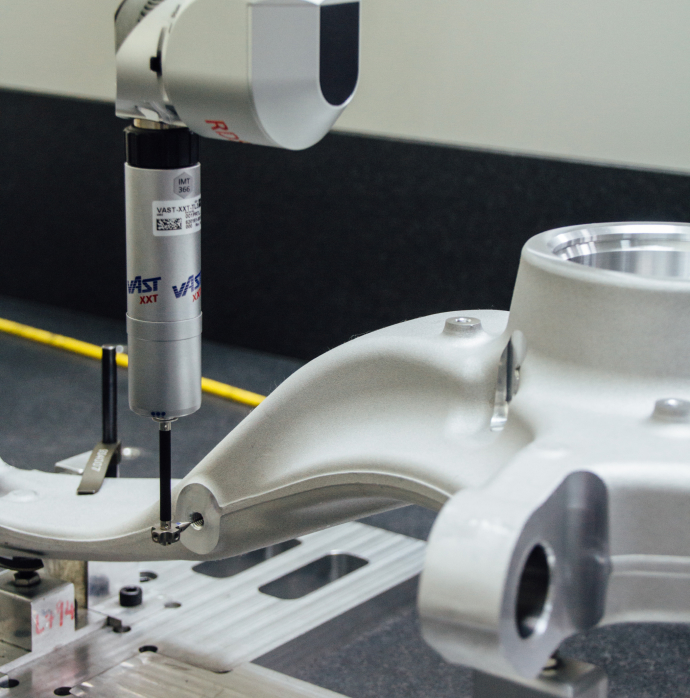

We make long-term investments in research and development, as well as hiring master and doctorate talents specializing in areas including new materials R&D, forging and forming technology, heat treatment technology, precision machining, surface finishing, and composite materials. Apart from supporting product R&D, testing, and validation, our accredited aerospace-grade mechanical test laboratory, corrosion test laboratory, and fatigue test laboratory also maintain close contacts with research and educational institutions to facilitate technological capacity improvement.

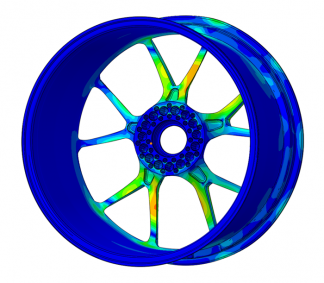

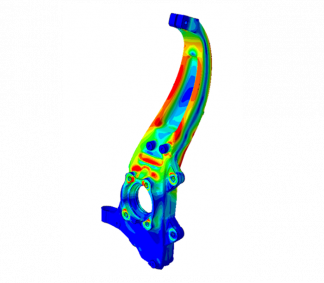

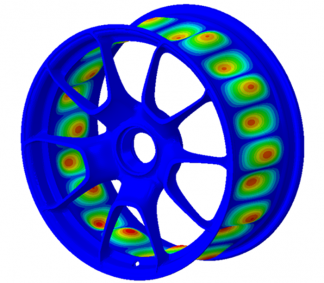

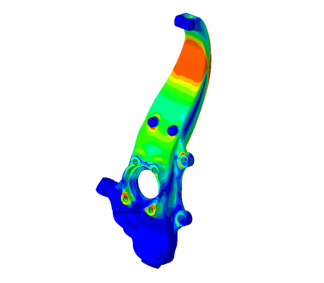

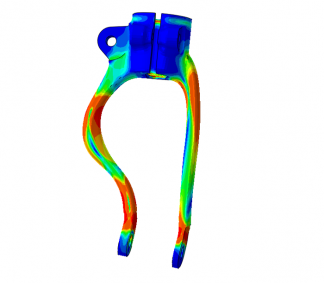

Product design of wheels and suspension systems parts

Establish parameters for style design, structural design and analysis, aerodynamics, dynamic movement intervention of spatial use, static and dynamic strength, and fatigue strength to provide lightweight design references and meet customer demands.

Lightweight materials development and database

Develop and design composite materials with aluminum, magnesium, titanium alloy, and carbon fiber to improve materials performance, and construct databases for process optimization, fatigue properties, corrosion-resistance properties, and heat treatment to establish specifications for materials use so as to maximize the material limit.

Secondary aluminum

Our self-imposed recycled aluminum RESAICAL used in forging has passed customer certification, and has been introduced to mass production. We will continue to promote the lightweight solutions of automotive suspension systems, invest in equipment and R&D to expand the scope of technology

Partners of academic and research collaboration