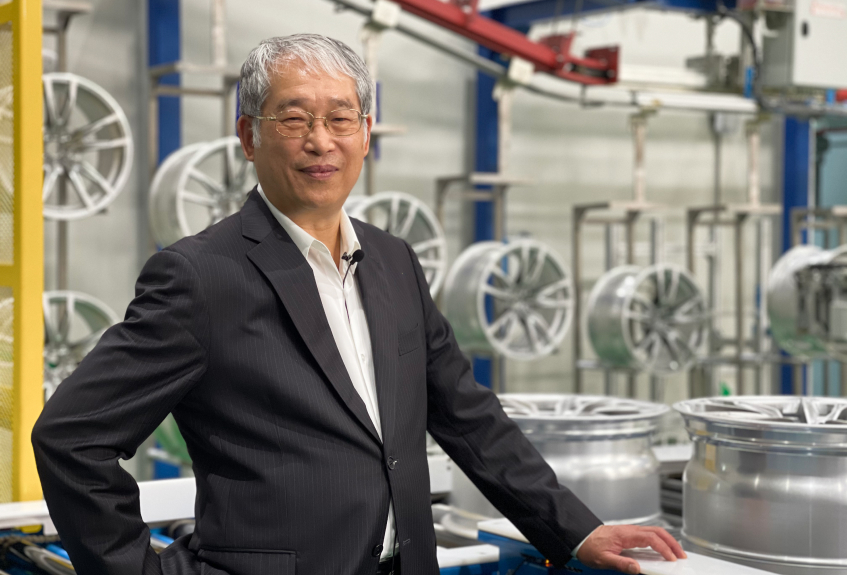

Despite continuing challenges in 2023, including global economic fluctuations, inflation, and geopolitical issues, the gradual normalization of shipping costs and the smoothing of supply chains have contributed to a rebound in global passenger car sales. Notably, the luxury car market has maintained steady demand regardless of economic conditions, driving consistent growth. This positive trend has significantly boosted the utilization rates of SAI’s Yunlin and new Pingtung factories. As a result, our consolidated annual revenue for 2023 reached NT$7.779 billion, representing a year-over-year growth rate of 21.52%, a historic high. We extend our gratitude for your support and the dedicated efforts of all our employees.

Since the establishment of the “Sustainable Development Committee” in 2022, we have consistently embedded the principles of ESG into our policy decisions. In 2023, we further established a comprehensive implementation framework, defining four major pillars and commitments as the blueprint for SAI’s sustainable development.

These pillars are: advancing towards net-zero emissions, co-creating a sustainable supply chain, building a happy enterprise, and promoting shared prosperity. Each pillar is accompanied by clear strategic goals and action plans, aiming to enhance SAI’s contribution to sustainability and its value. In terms of corporate governance, the newly elected Board of Directors in 2023 includes two female directors, with independent directors making up 40% of the board. This not only demonstrates SAI’s commitment to diversity in governance but also includes the appointment of Professor LIOU Wan-Yu, who has a professional ESG background, as an independent director, significantly

bolstering SAI’s ESG sustainability competitiveness.

Looking ahead, SAI is confident in its overall operational growth and has applied for listing on the stock exchange at the end of 2023. We anticipate that listing will further enhance our corporate image and value, attract and retain top technical talent, and diversify our capital market fundraising options. The entire SAI management team will continue to strive towards our mission of providing customized low-carbon wheel solutions and leading the green transformation of the automotive supply chain. Together with all our employees, customers, and suppliers, we will build a green supply chain, achieve green growth, and promote shared prosperity for all!

Sustainable Operations

We aim to become the optimal supplier of the industry, improve human living quality, and create a sustainable, all-win happy enterprise.

Performance-oriented: We introduce a market-competitive compensation system and set competence and contribution as the key performance indicators of compensation and promotion. We also encourage employees to sow more effectively and efficiently so as to reap more.

Continual improvement: Make continual improvement in all aspects without overlooking any point, and find the root cause of all problems to prevent recurrence.

Total participation: Encourage employees to make various recommendations, proposals and action plans, respect and trust one another between labor and management and among departments so as to make a better SAI through collaboration.

Right persons for right places: Respect the expertise and specialty of employees, and assign the most suitable job and duty to employees by role and responsibility.

Teamwork: Value collaboration, share information and inherit experience, actualize oneself to achieve others, accomplish targets through teamwork.

Self-discipline and accountability: Maintain self-discipline, make defined and detailed plans, improve execution capability, finish the job and finish it well, and set higher standards continuously.

Learning and innovation: Enjoy continuous learning, absorb new knowledge, and make continual improvement and innovation with what is acquired.

Stakeholders

Capturing and listening to the issues that concern stakeholders is the fundamental to enforce sustainable business operations. We set specific communication channels for different stakeholder groups and accept and address the needs of stakeholders for the reference of realizing ESG. Through systematic assessment, we draw up the questionnaires for stakeholders and material topics in accordance with the GRI Standards and gather the opinions of stakeholders through questionnaire survey to prioritize handling and response so as to meet the expectation of stakeholders.

Material Topics

The Company adopts the Double Materiality principle as proposed by the European Union, integrating economic, environmental, and social impacts along with operational impacts into significance analysis considerations. The integrated ranking calculation is as depicted in the following figure.

Additionally, we consider SASB industry topics, peer-reviewed material topics, and last year’s material topics. We have consolidated the “Raw Materials Management” issue with “Green Innovative Products” and included “Energy Management” as a distinct topics, establishing 13 material topics.