Quality

We value customer feedback and after-sales service during product development and production. Through continual quality improvement, we meet our customer’s requirements for quality management and provide products and services of the highest quality.

Quality Policy

Customer Satisfaction

Listen to customer feedback, foresee market demands, create market value, and assure customer satisfaction.

Total Partition

Through employee partition, we actively develop and improve process technology and build quick response capability.

Continual Improvement

Through continual improvement, we meet higher quality standards and provide better services and total solutions.

Methodology

IATF 16949 Standards and Core Tools

Quality Assurance

Over the years, we have passed the certification of different standards and systems through the audits of customers, government certification bodies, and third-party certification bodies. These suggest that our systems for quality management, environmental management, occupational health and safety, energy management, and laboratory management meet the international standards and requirements, enabling us to provide customers with satisfactory, optimal products and services.

ISO 27001 : 2013

ISO 9001 : 2015

ISO 14001 : 2015

ISO 17025 : 2017

ISO 45001 : 2018

ISO 50001 : 2018

ASI Performance Standard

IATF 16949 : 2016

Ford Q1

JWTC VIA

Brazil Inmetro

Indonesia SNI

JLRQ

Vietnam VR

Equipment Highlights

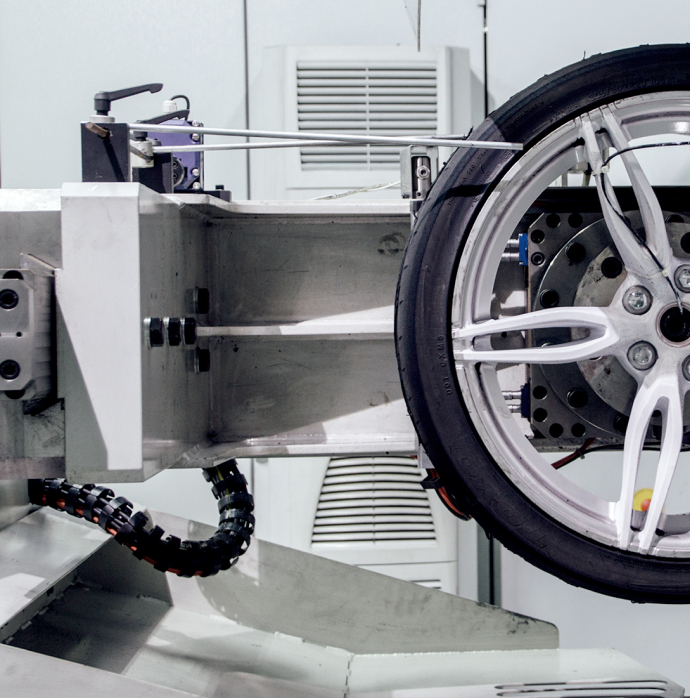

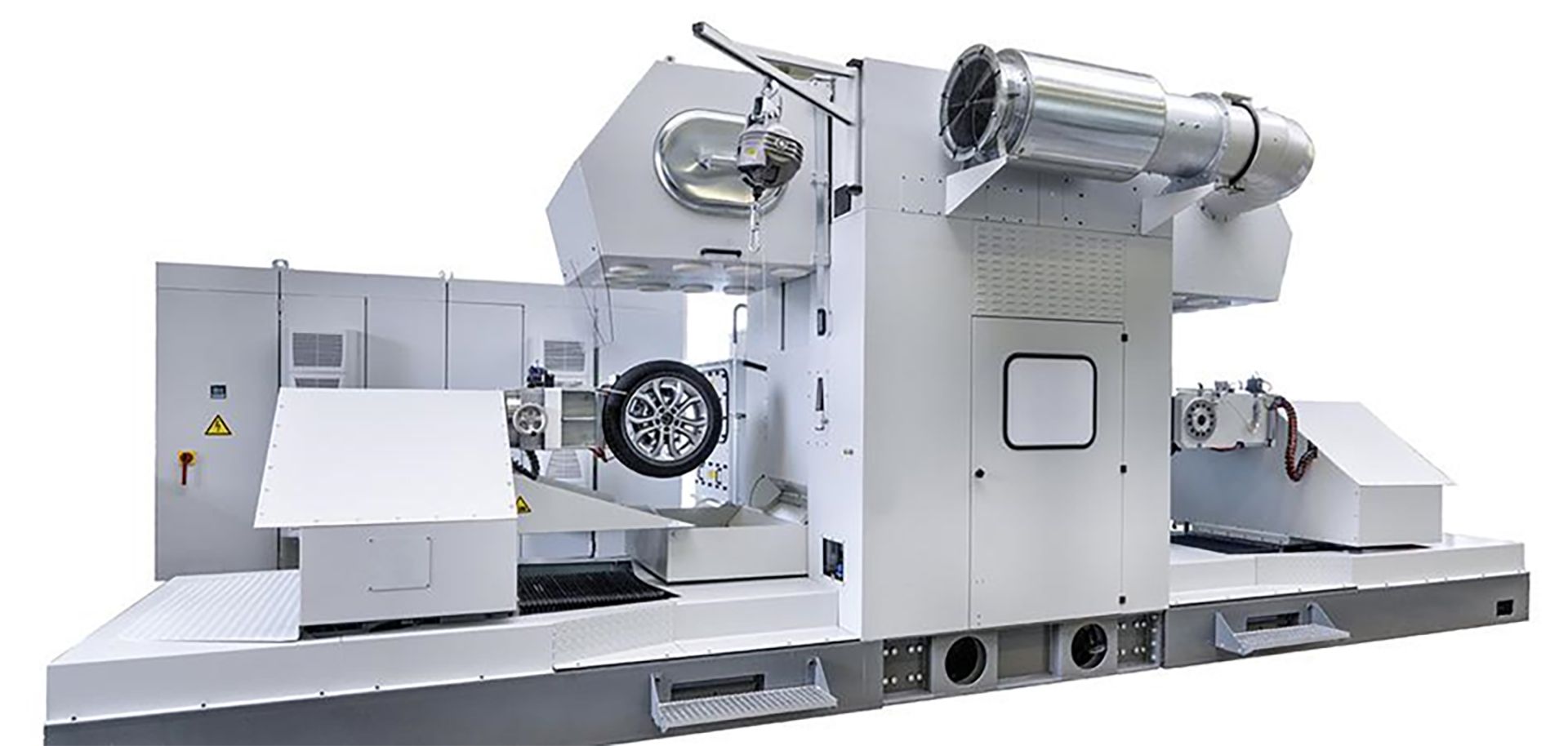

Bi-axial Test

Currently, our Marka bi-axial test bench is the only one of its kind in Taiwan.

Bi-axial Test

The Nürburgring is located in Nürburg, Rhineland-Palatinate, Germany. In 1920s, the ring was built around a small village and medieval castle in Nürburg near the Eifel Mountain. This ring is challenging as it is a very long and runs across complex terrains. Apart from being considered as the world’s most demanding ring built for car racing, it is also the field for the durability and performance tests before mass production of new car models. The bi-axial test simulates the Nürburgring to test wheels on the toughest road surface and load-carrying condition and thereby validate if the wheel design and manufacture meet the requirements for the toughest road surface.

Bending Fatigue Test

Bending Fatigue Test

The bending fatigue test simulates the bending moment that wheels must resist under repeated fatigue to verify the lifespan of spokes and the hub and thereby ensure that no cracks or loosened bolts (nuts) or other vehicular hazards will occur.