History

1994

- Founded SAI in Xiluo Town, Yunlin County, to produce forged bicycle parts and golf heads.

2000

- Relocated to Yunlin Technology-based Industrial Park in Douliu City, Yunlin County, and changed the Chinese company name into the current company name.

2001

- Passed QS 9000 quality standard certification.

- Expanded to the US market and became the forged wheel supplier of General Motors of the USA.

2003

- Certified by TUV NORD according to ISO 45001 Environmental Management System

- Construction of the Yunlin plant II.

2004

- Certified by TUV NORD according to ISO/TS 16949 Automotive Quality Management System and ISO 9001 Quality Management System.

2006

- Became the forged wheel supplier of Ford Motor of the USA.

2007

- Became the forged wheel supplier of Chrysler of the USA.

- Became the forged wheel supplier of Toyota Racing Development of Toyota Motor North America.

- Passed the FORD Q1 certification.

- Passed the certification of Japan Light Alloy Wheel (JWL) standards for sedans.

- Certified by TAF according to ISO 17025/IEC Laboratory Management Systems.

2008

- Became the forged wheel supplier of Jaguar Cars Limited of the UK.

- Became the forged wheel supplier of Tesla electric cars of the USA.

- Became the supplier of forged flight seat structures of Aerospace Industrial Development Corporation (AIDC).

- Earned the Gold Award from Toyota Quality Alliance.

2009

- Became the forged wheel supplier of Adam Opel AG of Germany.

- Certified by TUV NORD according to ISO/OHSAS 18001 Occupational Health and Safety Management Systems.

- Passed the certification of Japan Light Alloy Wheel standards for trucks (JWL-T).

2010

- Became the forged wheel supplier of Bayerische Motoren Werke (BMW) AG of Germany.

- Became the forged wheel supplier of Holden Special Vehicles (HSV) of Australia.

- Became the forged wheel supplier of Honda Motor of Japan.

- Passed the KBA/TÜV automotive certification of Germany.

- Certified by TUV NORD according to ISO/AS 9100 Aerospace Management Standard.

- Awarded the Commendation for Job Opportunity Creation by the Executive Yuan.

2011

- Became the forged wheel supplier of Mercedes-AMG GmbH of Germany.

- Became the forged wheel supplier of Dr Ing. h.c. F. Porsche AG of Germany.

- Became the forged wheel supplier of Jaguar Land Rover Limited of the UK.

- Became the forged wheel supplier of McLaren Racing Limited of the UK.

- Earned the 19th Taiwan Excellence Award,

- Earned the Chrysler Quality Award.

- Earned the Platinum Award from Toyota Quality Alliance.

2012

- Became the forged wheel supplier of Ferrari S.p.A. of Italy.

- Became the forged wheel supplier of Volkswagen AG of the Germany.

- Became the forged wheel supplier of Rolls-Royce Limited of the UK.

- Became the forged wheel supplier of Alpina Burkard Bovensiepen GmbH & Co. KG of Germany.

- Became the forged wheel supplier of Toyota Motor Corporation of Japan.

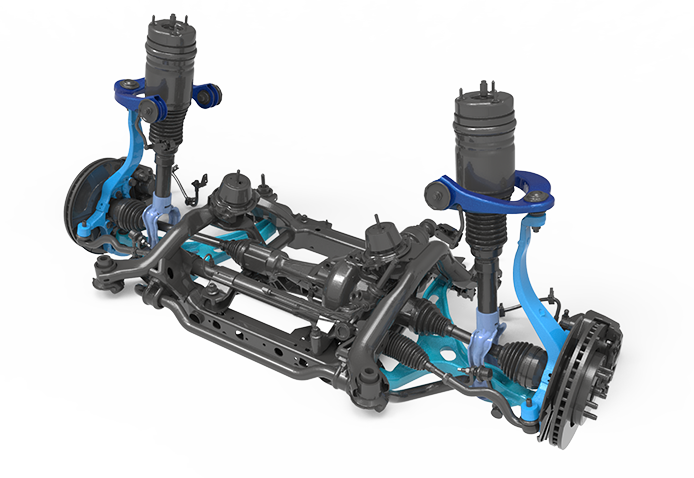

- Became the forged suspension system parts supplier of Bentley Motors Limited of the UK.

- Became the forged suspension system parts of Jaguar Cars Limited of the UK.

- Passed the accreditation of National Aerospace and Defense Contractors Accreditation Program and entered the forged suspension system parks market.

- Passed the Brazil Inmetro wheel product safety certification.

- Earned the Gold Award from Toyota Quality Alliance.

2013

- Became the forged wheel supplier of Bentley Motors Limited of the UK.

- Became the forged wheel supplier for MINI cars by Bayerische Motoren Werke (BMW) AG of Germany.

- Became the forged wheel supplier of Ducati Motor Holding S.p.A. of Italy.

- Became the forged suspension system parts of Mercedes-AMG GmbH of Germany.

- Became the forged suspension system parts of Jaguar Land Rover Limited of the UK.

- Earned the 1st Taiwan Mittelstand Award from the Ministry of Economic Affairs.

2015

- Became the forged wheel supplier of the Acura label under American Honda Motor Co., Inc. of the USA.

- Became the forged wheel supplier of Dongfeng Motor Corporation of China.

- Became the forged suspension system parts of Bayerische Motoren Werke (BMW) AG of Germany.

- Became the forged suspension system parts of Rolls-Royce Limited of the UK.

2016

- Became the forged wheel supplier of Audi AG of Germany.

- Became the forged wheel supplier of Karma electric cars of the USA.

- Became the forged wheel supplier of the Lexus label of Toyota Motor Corporation of Japan.

- Became the forged wheel supplier of Faraday Future electric cars of the USA.

- Passed the Indonesia SNI automotive components certification.

- Earned the JLRQ Award as a Jaguar Land Rover quality supplier.

2017

- Completion and inauguration of the coating plant in Freudenstadt, Germany.

- Became the forged wheel supplier of Daimler Manufacturing Company of Germany.

- Certified by TUV NORD according to IATF 16949 Automotive Quality Management System.

2018

- Became the forged wheel supplier of Volvo Personvagnar AB of Sweden.

- Became the forged wheel supplier of Aston Martin Works of the UK.

- Certified by TUV NORD according to ISO 45001 Occupational Health and Safety Management Systems.

2019

- Became the forged suspension system parts of Lotus Cars Limited of the UK.

2020

- Started the operation of the Pingtung Plant. Passed the OEM certification for RESAICAL recycled aluminum.

- Became the forged wheel supplier of Workhorse electric cars of the USA.

2021

- Earned the Gold Certificate of Excellence from General Motor.

- Certified by TUV NORD according to ISO 45001 Energy Management Systems.

2022

- Shipped the 10 millionth wheel.

- Became a member of Aluminium Stewardship Initiative (ASI).

- Awarded the Outstanding Enterprise at the 19th National Brand Yushan Award.

- Awarded the Best Product at the 19th National Brand Yushan Award.

2023

- Certified by TUV NORD according to ISO 27001 Information Security Management System.

- Passed the ASI Performance Standard Certification.

2024

- IPO