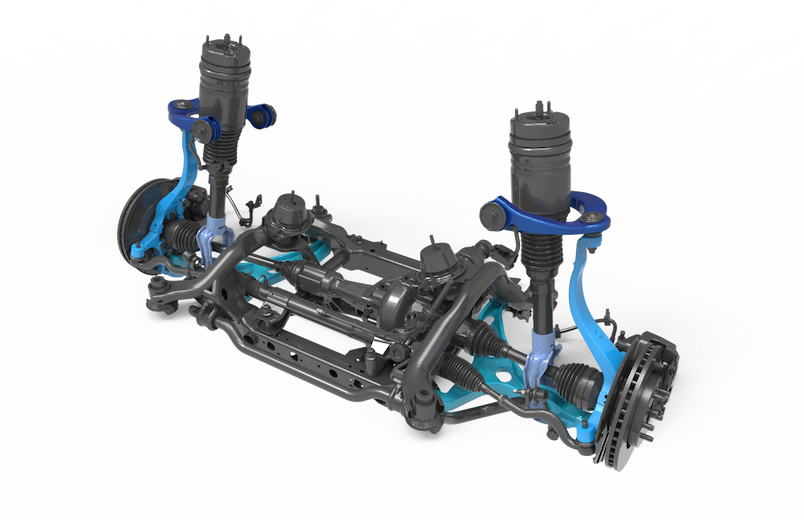

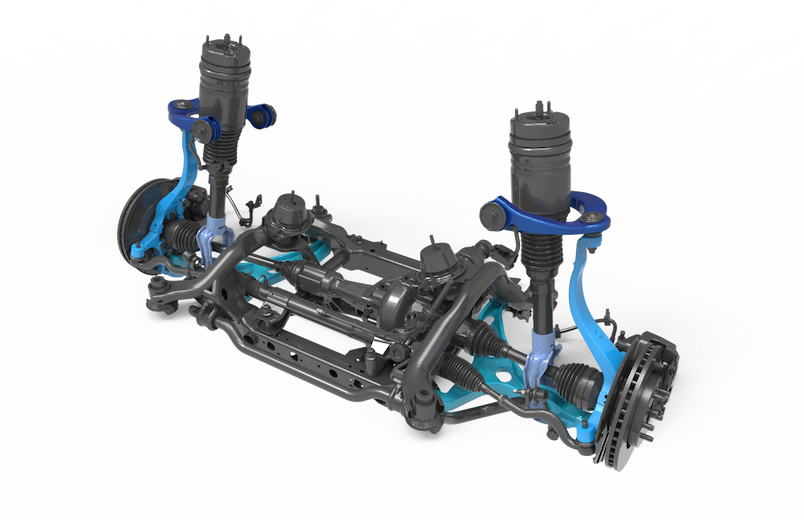

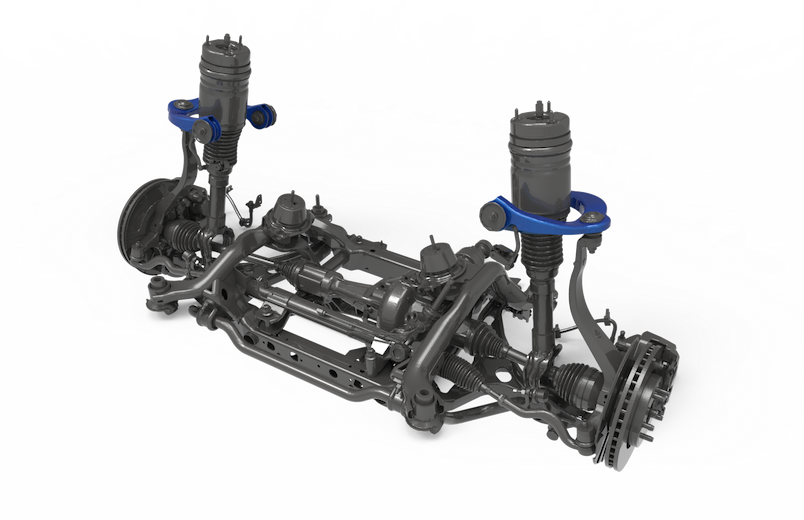

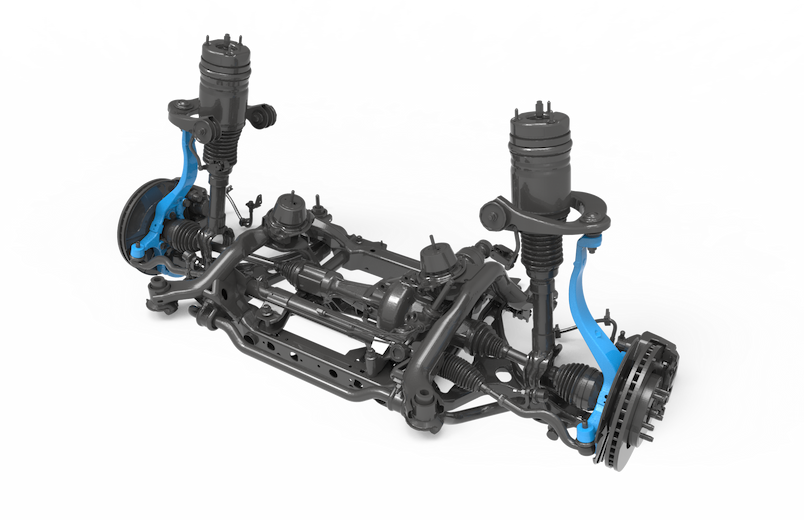

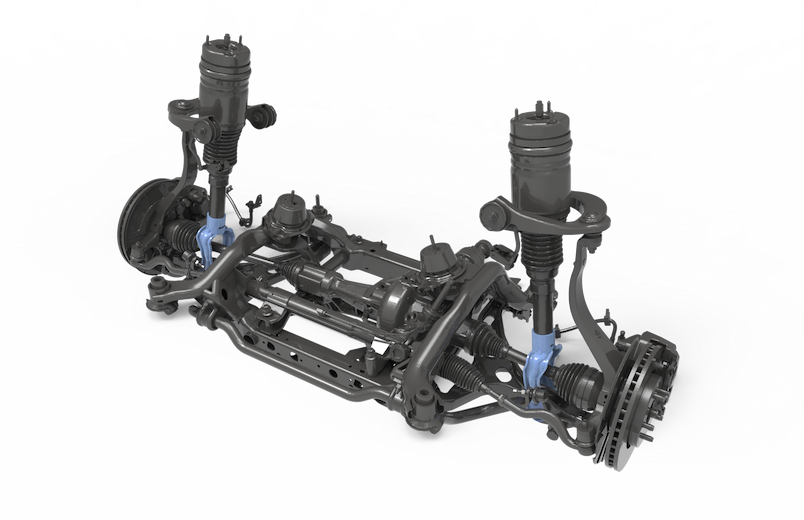

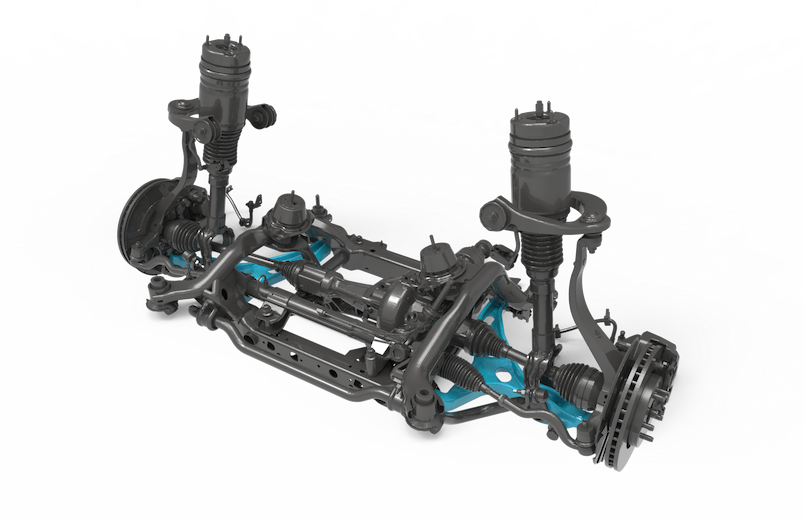

Suspension parts

Energy-efficient, low-emission, high-strength materials, and lightweight structure design are the development trends of the automotive market. The suspension system assembly is an integration of all part and component modules and systems that enables drivers to enjoy absolute comfort and stable handling for safety during driving.

During the development, the structure design of various parts and components of suspension system modules, the technique and technological requirements, process parameters and conditions, composition of materials, and assembly load limits require highly meticulous calculation. To ensure the lightweight design of each part and component, it is necessary to consider the load tolerance and spatial intervention of adjacent parts. Hence, it is a complicated, complex, and highly professional technology.

With mature advanced metal forming and forging techniques and technology, we provide optimal forming solutions according to the appearance, structure, and performance requirements of products through collaborative development with our customers. We also possess the design and manufacturing capabilities for mold development to enable quick product development and sample submission, as well as quick response to the design changes of customers. In additional to our complete forging production line, we have advanced automated machining lines, automated assembly capacity, and externally accredited laboratories. Online and offline control with automatic measurement, monitoring mechanisms, and quality monitoring systems are used for each production procedure to ensure each safety component can pass the most stringent quality control and is delivered to customers as scheduled with the required quality.

Suspension parts

- 1

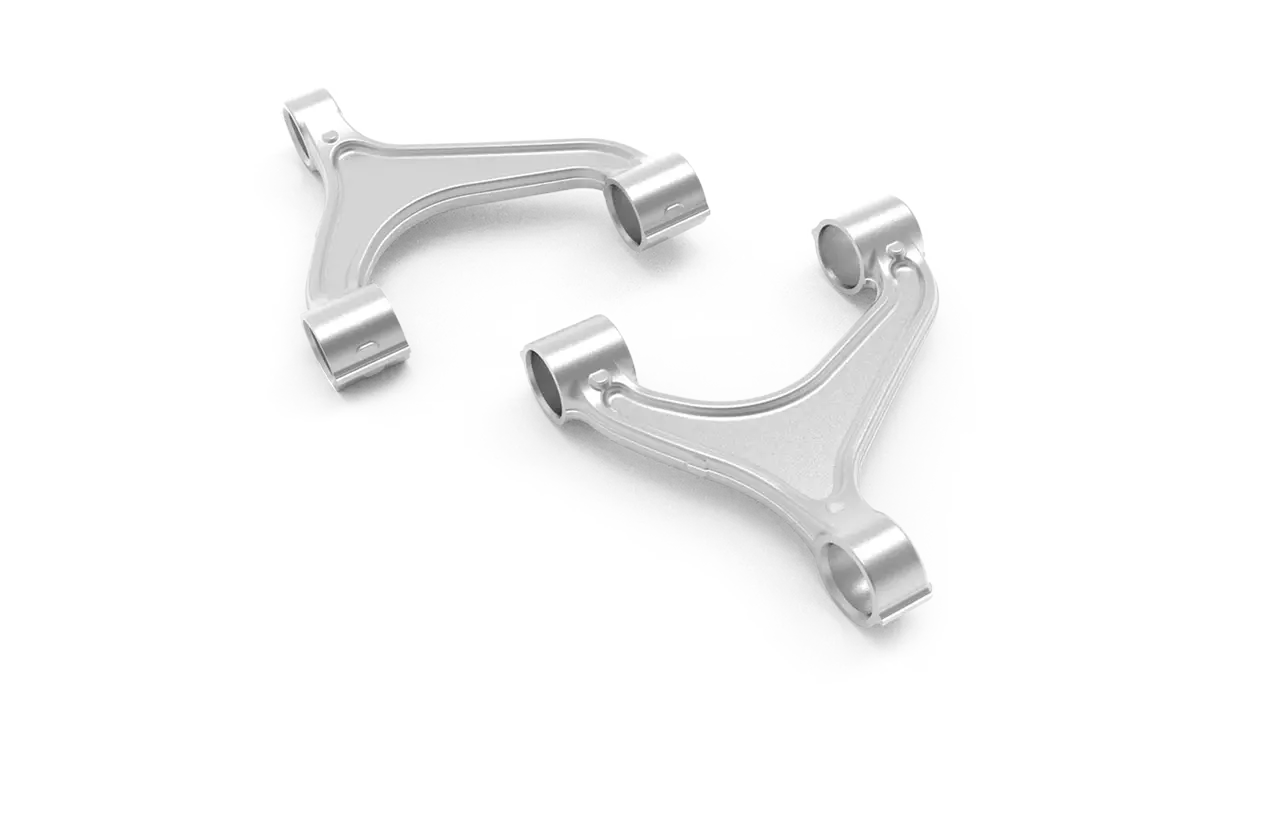

- 2

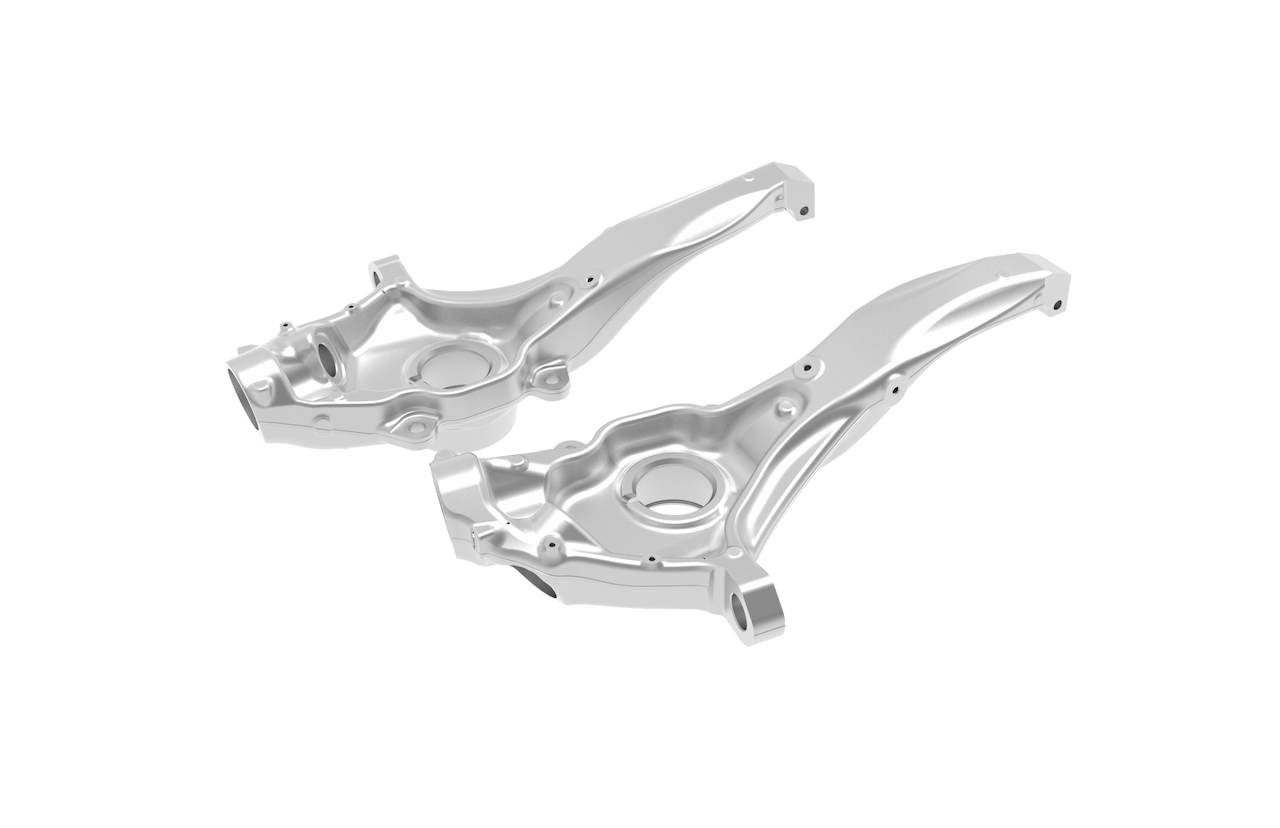

- 3

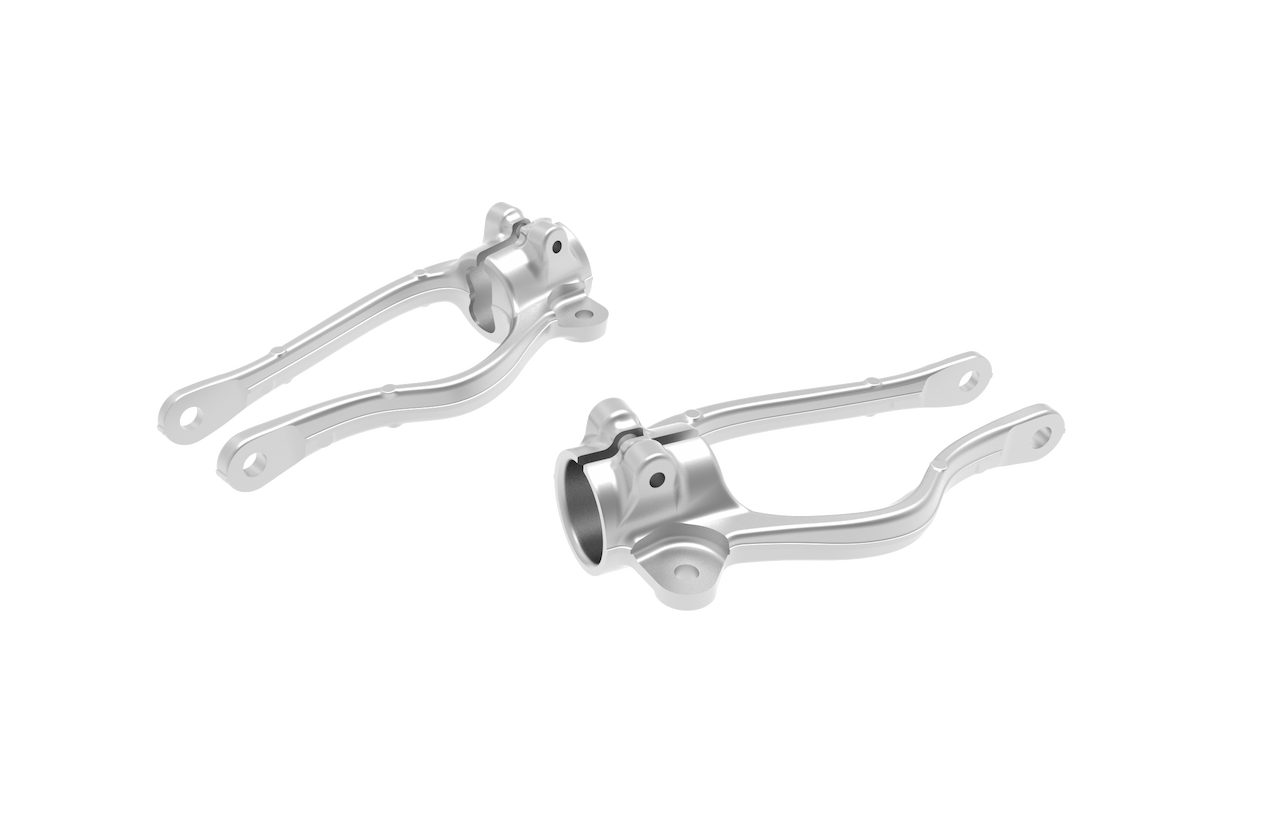

- 4

- 1 | Upper Control Arm

- 2 | Knuckle

- 3 | Damper Fork

- 4 | Lower Control Arm